Limits of Lean

We will use the current term, Body Position (BP). BP is a valuable tool that all good motorcycle road racers, and to some level, track day riders, need to use when needed. The key words to notice are "When Needed". There are many different styles, but they all try to accomplish the same result. There are many misconceptions and a lot of hyperbole about the effects of BP. In this chapter, when we refer to BP, we are talking about moving our weight either to the right or to the left of the centerline of the motorcycle. Moving weight forward or rearward is a different discussion.

All motorcycles have what I refer to as "The Mechanical Limit of Lean Angle".

1. Ground clearance of the chassis and/or

2. The edge of the tire tread.

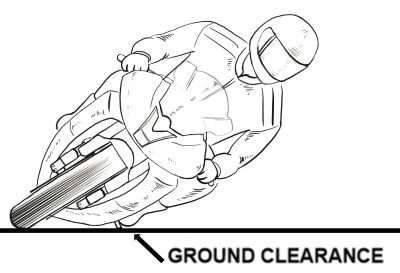

1. Ground Clearance

The first and most obvious limit to lean angle is Ground Clearance. Ground clearance is the mechanical limit as to how far you lean before parts of the motorcycle chassis physically start to drag on the ground. With today’s sport bikes, the first thing to drag is usually the lower fairing. In years past the exhaust pipes, mufflers and or the foot pegs were the first to drag on the ground. The ground clearance back then was so limited that we would drag parts of the bike long before we used up all the traction. Even at that, aggressively dragging of the hard parts of the motorcycle will reduce the total weight on the tire contact patch. Less weight on the contact patch will reduce the available traction and allow the tire to slide. A lot of effort went into trying to improve our ground clearance, back then, by moving pipes and foot pegs etc. This is when the art of hanging off the bike started to develop. Eventually we got enough ground clearance to run out of traction.

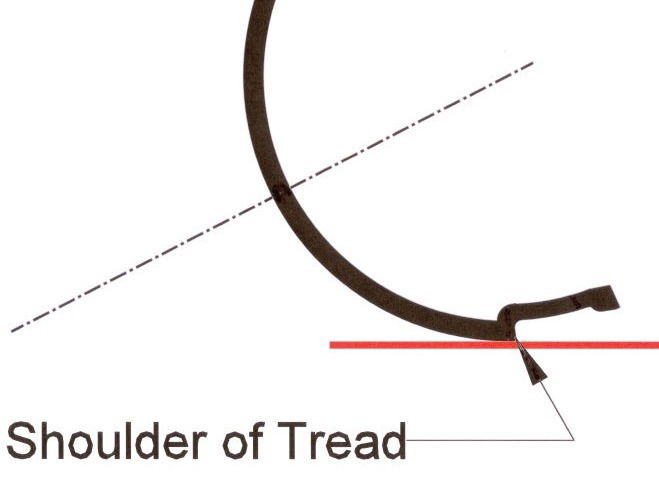

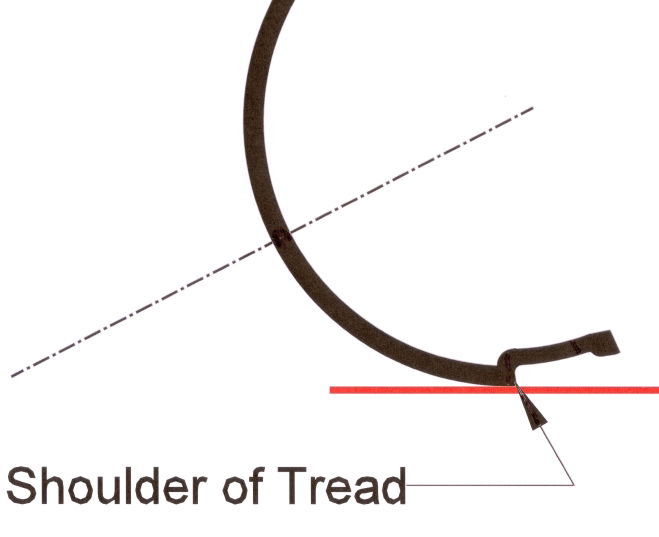

2. Edge of Tire

Some bikes have tremendous amount of ground clearance and can lean over far enough, for the racer to be on the Edge or Shoulder of the tread. This is where the tread and sidewall meet. The problem here is the size of the contact patch is radically reduced in cross-section area. Now the racer has a lot less surface area trying to control the same amount of force and weight.

This will cause mechanical stresses such as, high shearing forces and elevated surface temperature of the rubber, etc. This small contact patch can start to tear and/or shred. This is often referred to as “cold-tear”. This significant reduction in contact patch size could even cause the rubber to overheat and soften too much and start to tear or melt. The contact patch will also start to strain and deform under the increased stress. This deformation can cause the bike to feel unstable. It is not uncommon for a tire in this situation, with no warning, to suddenly and completely, break loose, causing the racer an exciting moment or two.

The result of exceeding either of the limits of lean, the tire will ultimately start to slide.